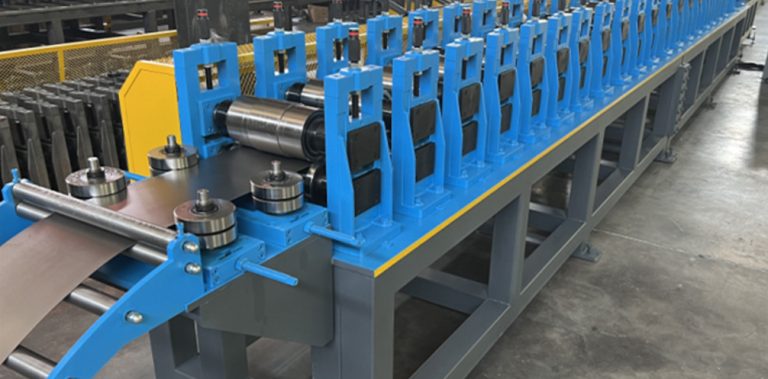

steel rolling shutter octagonal tube roll forming machine

Steel Rolling Shutter Octagonal Tube Cold Roll Forming Machine

1)Processing material:steel strip

2)Material thickness:0.6mm-1.0mm

3)Formed sizes on one machine:one line for 40 tube,the other line for 60 tube

4)Main motor power:4kw+4kw

5)Cutting power:3kw

6)Productivity:4m-12m/min

7)Roller stations:22 sets

8)Roller material:GCr15 with vacuum heat treatment&precise lathing&chrome coating

9)Active shaft material:45#steel with high frequency surface treatment and grinding process

10)Shaft diameter:Ф50mm

11)Cutting system:tracing cutting type with 1.5kw servo motor,can cut to any length you need

12)Cutting blade material:high speed steel

13)Wall plate:20mm thickness Steel plate

14)Based frame:Welded by 100mm48mm5mm national standard beam channel,the top is covered with 10mm thick steel plate

15)Transmission type:double chains

16)Reducer:Cycloidal pin wheel type

17)Bearing:Single type

18)Control system:SAJ transducer,Xinjie touch screen,Xinjie PLC,Zhengtai for other electric parts

19)Power supply:380V,3 Phase,50Hz

20)Accessories:5 ton electric decoiler with leveling device(2 sets)

40 ton punching machine with servo feeding system(2 sets)

3m output table(2 sets)