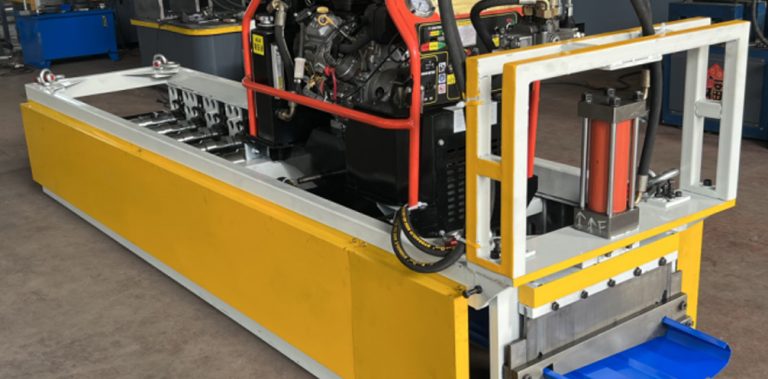

ridge cap roll forming machine

Roofing Ridge Cap Roll Forming Machine

1) Processing material: color steel coil, thickness 0.4mm-0.7mm

2) Formed sizes on one machine: as per above profile drawing

3) Productivity: 0-3m/min

4) Cutting system: Hydraulic non-stop cutting system, the length is adjustable

Cutting die material: Cr12Mov

5)Punching system: Hydraulic non-stop punching type, the holes distance is adjustable

punching die material: Cr12Mov

6) Roller stations: 14 steps

7) Roller material: 45# steel with vacuum heat treatment &precise lathing&chrome coating

8) Shaft material: Ф60mm, 45# steel with high frequency surface treatment and grinding process

9) Wall plate: 210 type cast iron block, fixed on based frame by screws

10) Based frame: Welded by 100mm100mm4mm steel square pipe,

the top is covered with 20mm thick cold drawn steel

11).Driving type: double chains

12).Main motor: 7.5kw servo motor

13) Reducer: K87 hard surface gear type

14) Hydraulic station: Power: 5.5kw, with air cooling device

15) Counter: Omron

16) Control system: SAJ transducer, Xinjie touch screen, Zhengtai for other electric parts

17) Power supply: 380V, 3 Phase, 50Hz(or as per your request)