Steel Door Frame Roll Forming Machine with Punching Holes

Steel Door Frame Roll Forming Machine with Punching Holes

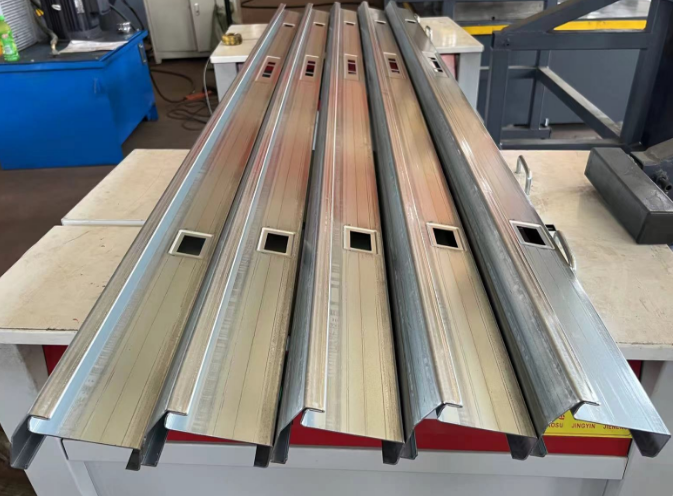

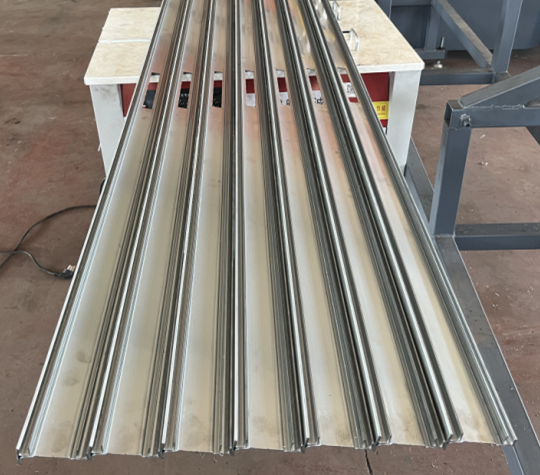

1)Processing material:galvanized steel coil

2)Material thickness:1.5mm

3)Formed size:as per profile drawing above

4)Main motor power:7.5kw+7.5kw

5)Pump power:7.5kw

6)Productivity:0-5m/min

7)Roller stations:35-40 steps

8)Roller material:Cr12 steel with vacuum heat treatment HRC57°-60°

9)Active shaft material:40Cr quenched and tempered,processing by lathe and cylindrical grinder

10)Shaft diameter:Ф50mm

11)Hydraulic cutting&punching system:automatic stop-punching&cutting type,the distance

between each two hole-units is adjustable,can cut to any length you need,

12)Cutting blade/punching die material:Cr12MOV

13)Machine construction:as per machine photos

14)Transmission type:GEARBOX

15)Control system:computer control box with inverter

16)Power supply:380V,3 Phase,50Hz(or as per your request)